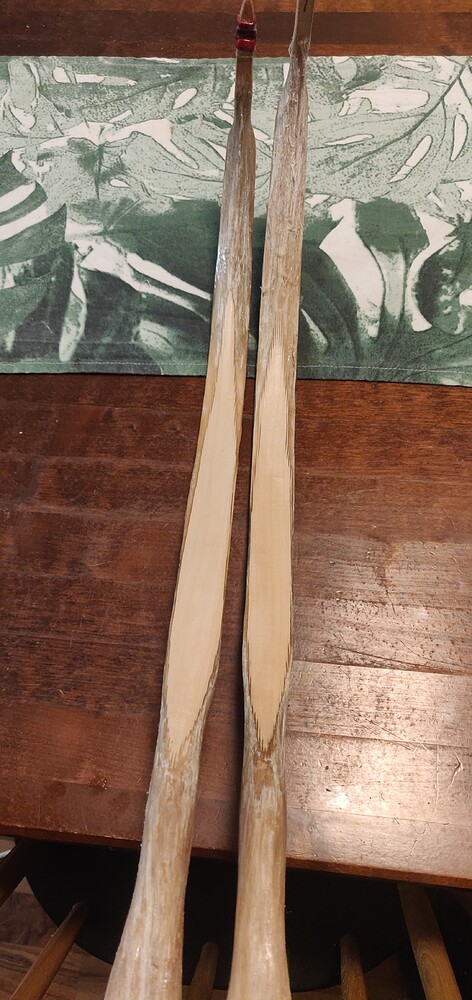

Note to self, don’t bend new bows at 30-35% humidity. These are new/old target bows, tatar and turkish. Not happy, but i think the wood can be ground down and glued fresh wood on top.

Not really proud of this hassle right here… But i can change the headline now to “broken core repair”. ![]()

Maybe this is helpful for others, i think this is pretty easy to fix. Compared to the various other joinery we do and get away with it. ![]()

I’ll first test on a old bow. I have 5 bows in total waiting for repair now… But its all cool.

Hope, you will be successful, but I am quite interrested - what are your criteria ( please, could you explain in details ) when choosing “optimal” wood for core / patch?

Thanks !

Thanks. You want fresh cut maple/elm or something you can verify is healthy. Healthy meaning after cutting it was stored inside where no fungus or such could start to rot it.

Many hardwoods are suitable but people like sugar maple or norwegian maple the most. Also elm, ash and such make good bows.

You want to find a big, thick trunk of wood to be cut into slats. Thin branches will most likely have knots. I don’t think growth ring size is really important or even aligning growth rings (horizontal vs vertical).

I have a lot of belief for this maple i have here, only my stupidity that i could break these cores here when it was winter (cold and dry).

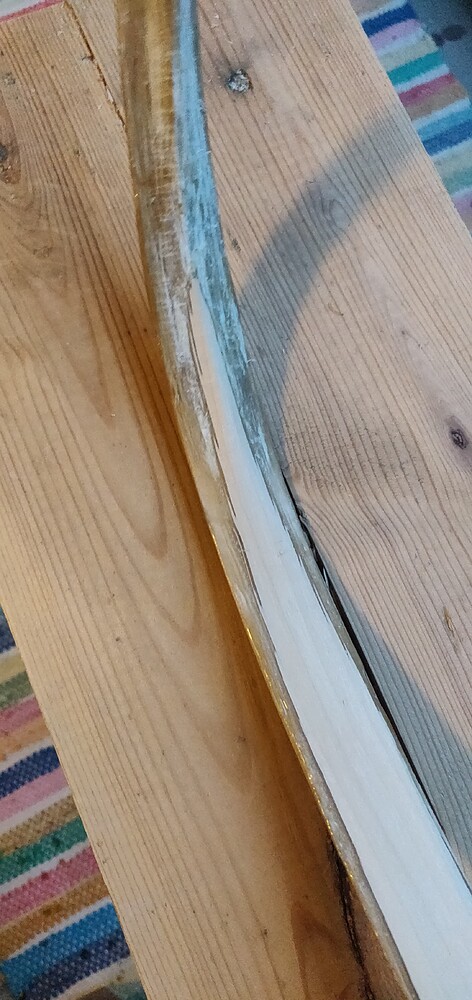

Soon grooves are full in both pieces. Maybe tomorrow i glue this up. It will be a bit uncomfortable glue up, since the parts are a bit too weak for rope&tencik, but the spring or screw clamps dont provide sufficient pressure… Maybe i will do some sort of mix. Add wedges on rope to manipulate tension.

Very interesting to see, I didn’t know repairs like this could be done. Have you done it previously or seen someone else work?

Yes, i haven’t either tried this before. The idea just popped into my mind and i had some encouraging comments from other experienced bowyers.

This is a common fix on woodbows, but on the belly side. Its called a “bloom” apparently. With wood bows and belly side its really safe since there are no tension in there.

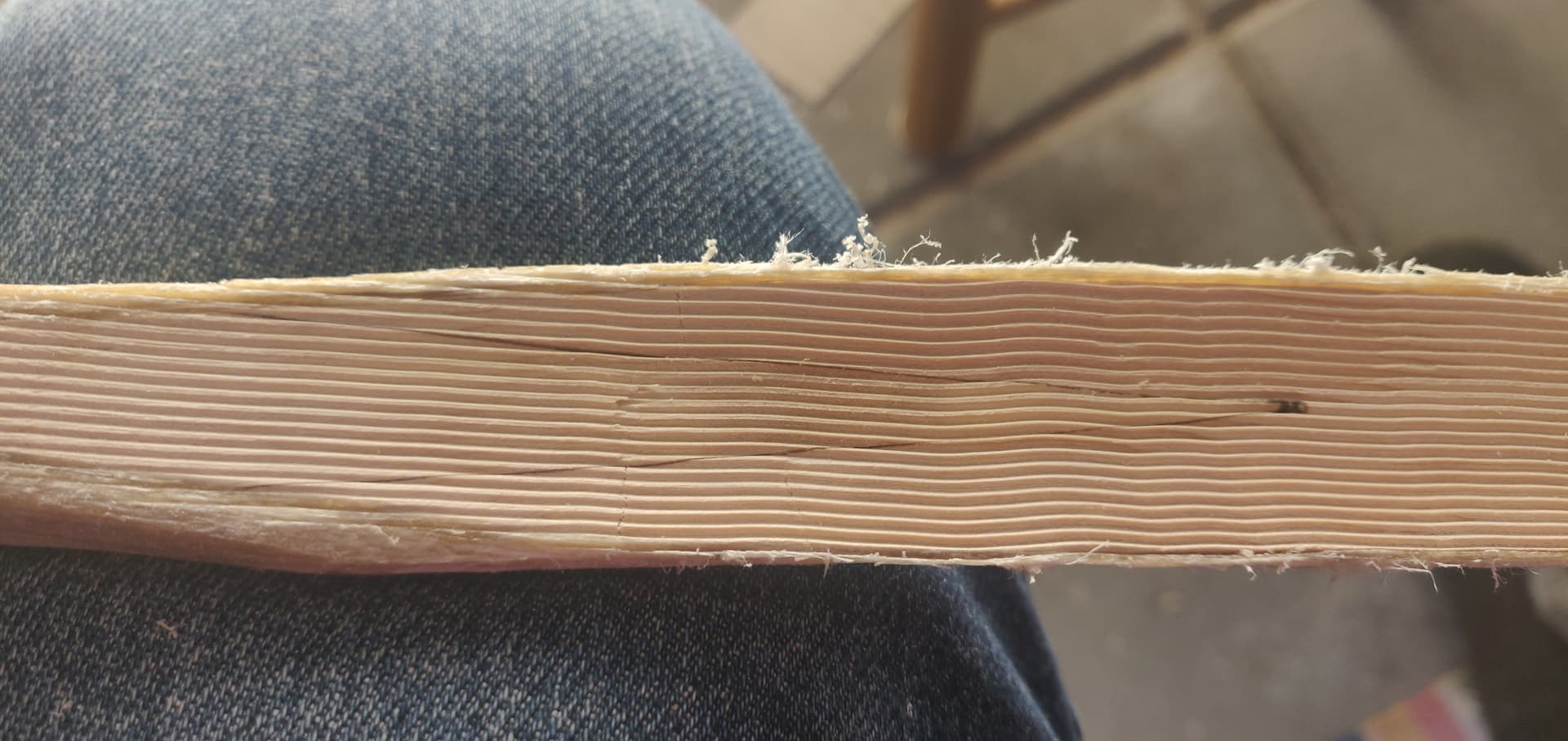

In general my joint here will be really strong since the ends of this thin piece will be in the handle and mid of kasan. The only concern is that i had to leave a little bit of wood on the bottom, that still has the fractures - like only 1-2mm thick wood. But… the science tells first of all sinew takes away most of the tension and then this new wood with thickness of 3-4mm should do the rest.

First two bows glued. I heated the parts and then ended up using simple clamps. The fit is pretty good but also it felt really hard to press the now straightened piece of wood on to the core. Gluin (wetting) the wood piece straightened my heat manipulation, so there was quite a lot of clamping pressure needed to have it conform grip and kasan bend.

I hope it works, if so I can walk in your footsteps

First two bows got a sinew layer. A picture is missing of grooving that i do for the base.

The joint ended up pretty close to kasan eye actually… But it gets so thin over long distance, that i don’t think it creates a weak spot anywhere.

Bold project, looking forward tot he result!

Yes, we got to be bold now to learn. I have high hopes it works. I’ll lay the last sinew layer in upcoming days.

Welcome to the forum Alex.

Well, i think this project was doomed from the start. I’ll explain a little…

In general i think this joint works just fine. However with my bows, the problem was not with wood quality, amount of sinew or anything else. Problem was the (grip) core taper and general shape with some of the bows. Really reflexed shape and thin areas near the grip really pushed the bend too close grip. It basically destroyed all the bows, since there is no way to make up for that.

I could have added more wood there when i was doing the fixing joint, but doing that for all of the bows in both limbs - it just dont make any sense.

Actually one bow that i fixed, broke the core AGAIN from the same spot. That led me to notice the obvious problem with core taper.

So maybe its better to forget these, re-use sinew and horn if its enough thick. Lets make better bows. ![]() Maybe not 8 bows at a time…

Maybe not 8 bows at a time… ![]()