OK.Got it.

Sorry I reposted the pictures on a different reply but it’s the foreward handled bow post.

After hearing some info about how an assyrian was put together with splices on the limb etc. I’m afraid that’s too difficult or risky for me to do.

I don’t agree using splices on a bending bow limb for durability reasons.

My thoughts of putting the handle into a deflexed position was to relieve the inner limbs more and create a more rounded full draw.I believe without it it will still be ok with the reflex on the tips yet.

As the bow is 57.75" long TTT.

I like the clean unwrapped look of the turkish bows.I have Adam Karpowczs’ book here to reference from.So I used the handle profile he displays.

It says there is an exponential decay when tapering the core from the handle end.

Does this still mean that the fade area meeting the limb can be flush with the limb yet?

The rest will become filled with the layinf of the sinew.

I’ve tried making 2 turkish horn bows long ago and must say they were horrible.

I went by Jefferey Schmidts way of don it then.Maybe in the future I will try again.It is quite a commitment to make these type bows and in awe at thosevthat crank them out.

I love my self bows and have become proficient in making them enough.I love my reflex or the absence of much set in any bow.

I acquired the TBB series books back in 2009.In it was a chapter by Jefferey Schmidt making horn bows.I still probably did’nt do it right but it would of been ideal if Adam Karpowicz would of got on board during the publication of the series.

I look forward to following along on this forum in the future.

Thank you very much!

With more thinking if I feel I need to wrap sinew at the fades I will despite the look.

Too much time invested to take chances is the train of thought here.

Shooting for a 50# @ 28" bow the core is a scooch over 5/16" thick coming out of the fades with remaining 1/8" horn and 1/8" sinew to make it 9/16" thick finished.

Those parameters have worked out for me before with backward handled one piece bows.

Here’s a picture of the set up.The 320 is 320/100ths of an inch thick coming out of the fades.A scooch over 5/16".

I’ve never had a bow string break or invert or throw a string while shooting.The only way as stated that could endanger the fade.

Cool, you managed to upload pictures. This discourse platform is quite a bit more flexible than primitivearcher smf forum. No limitation for picture quality etc.

I thought you would have deflex in the handle, but that looks like straight handle to me. Well you have the length and low poundage, so why not have a bit more reflex. If one were to make a egyptian/assyrian angular bow at 50#, it would need to be more like 44-48" bow, otherwise it would be pretty floppy and unstable. They were pretty narrow bows too.

Adam’s own book is worth a read. I assume you know it? Amazon.com

If you have horn belly and sinew backing, there is no need to wrap the handle area. Your limb thickness and grip setup is looking just fine. Just need some horn there and then to tillering.

This long bow will surely store a lot of energy. It will be a good bow for hunting. If you wanted to shoot light arrows and use thumbdraw, you could go down to 45" and still get 50# @30" or whatever you want to shoot. It would be faster with 400gn arrows.

Yes I’ve had Adams’ book for quite some time.The paper back version.Beautiful book.

Forgot to mention width…The bow is 1 and 1/4" wide at the fades.Paralell 6" then tapered a bit from there.

Angleing the limbs downward for a deflex either created a void hole at the tip of male part of handle or no complete flat wood for horn to attatch to in the grip section.I did’nt like that.

I might leave just a bit of spine of 1/8" wood from the handle joint.Sinew next to and over it while sinewing.Wood is the stiffest material on this bow.

I plan to reflex a good 11 to 12 inches.From previous bows done this way after tillering this usually leaves me with 9 to 10 inches resting with 7.5" to 8.5" getting to the arrow while shooting after 6 hours of bracing time.

I’ve had a chronograph for quire some time testing all bows I make.You may not believe it but with 8.5 grain arrows [425 grain] they usually hit the 200 fps mark.

Thanks for the encouragement.

I was just wondering again what is or if it is an advantage to a front handled bow?

After making countless different types of self bows/sinewed bows/or bamboo backed bows these horn bows are always an extra adventure to undertake.

Not to toot my horn any,but here’s just a few from the past.They range from 8 to 11 inches resting reflex.

That sounds like healthy reflex. Some turkish bows are actually quite “relaxed” in a way, don’t keep a lot of reflex. But they do shoot quick because of the low mass. My go-to target bow shoots 400gn arrows ~220fps and its 55# @27", 115cm/46" long.

So i do believe! For such highly energy storing bows, you could do good numbers with 10gpp or higher mass arrows too. Maybe similar to tatar bows, which are longer and store more energy than ottoman bows.

Your bows look good for shooting target or hunting. I’ve spent so much time honing flight bows that i have very little hornbows dedicated for normal use. ![]()

With forward handle do you mean the turkish grip shape or deflexed handle? I think the turkish handle was a good way of fitting horn to flat surface, but also keeping thickness in the handle. The quick fading out of grip came from needing lots of bending area to keep bow length short. This shortness allows for really fast arrowspeed when arrow mass is low. The grip is also nice in hand so why not?

Yesterday I read from primitive archer flight forum about Arvins 62" osage project. I made a similar 50# bow model in virtual bow and tested varying degrees of reflex and deflex. When bow was only with slightly reflexed tips (1,5" reflex) speed was 230fps with 200gn arrow (24" draw). But when i added handle deflex and kept the net reflex same (1,5") - speed increased to 250fps. Grip deflex allows for thicker limbs and i guess thicker is quicker as they say??

Yes the turkish grip is what I mean.Brilliant design for it’s purpose.Like the fit in the hand myself also with the slick and clean look overall it produces.Usually I try to make my bows bomb proof.The reason I’ve asked about the splices.

I’ll have to make a bunch to get real familiar with them.

Looked at your scithian bow for quite a while.What a project and bow in the end with all those parts and V splices.There is no doubt you should know the durability of those splices I’d say.

I understand the concept of less limb mass and more dry fire speed with little or no handshock.I got to shoot a 42" turkish horn bow at a bow making gathering some time ago.Very well made.It was the real definition of 0 handshock I must say.It did stack at 28" yet though.Which probably got the best out of it then.I could’nt hit a bull in the ass with it though…ha ha.

Outstanding speed from those little fellas.They are works of art your making IMO.

I’ve made those D/R bows in bamboo backed versions and always liked there performance.Kinda regret not putting this one into defllex really.All well another day another bow right???

I believe in comparing bows to bows though.10 grain to draw weight arrows for each bow.Kind of like comparing apples to oranges though for needs.

I try for more momentum and KE with my making of bows.Better pass through instances on big game then.Although my shots most times are’nt much more than 20 yards…ha ha.

Steve Gardner long ago enlightened me as to the concept of not needing all that much reflex to get good arrow speed.Met him at Mo Jam also.He liked the D/R design also.Excellent fella to talk to about bow making.He’s tried about every angle and version of a bow you could think of.

He never got into the sinew and horn route though.I learned stored energy is one thing but releasing it efficiently is another from him.

I’ve shot with Arvin at a bow making gathering before too.At Mo Jam in Missouri.Nice fella but kinda into himself mostly.He mostly copies what Steve has done.Everyone has their mentor though right.

Anyway what I really like is putting the FG boys in their place at the target range…ha ha.The risers on their D/R bows are huge compared to the turkish handles which don’t appeal to me at all.I’m glad they got to lug those things around in the woods and not me…ha ha.

Thanks for your insight.

To comment on the 24" draw with a 62" bow makes sense to stay away from set as most set begins after that draw length.Not something that is comfortably accurate for me.

Achievements using 4"-5" longer bows of 67"-68" with 4" longer draw have been done also by myself.

All wood bows of course.

My goals from analyzing the functions of bows for efficiency and pleasure I’ve derived from people like Tim Baker,Steve Gardner,and Adam Karpowicz.

Trying to find a happy medium in length of bow while keeping the draw length at 28" has led me to 56"-60" long bows.Using denser materials to keep the width as narrow as possible for higher toned vibration.

First I reduce inner working length of limbs and balancing them in length with lighter,stiffer less working outer limbs for better use of the mass on the limbs.

This also reduces limb vibration for 0 hand shock.

For me this is more easily accomplished using composite materials.It can be done to a degree with just wood also at times if the design is right.

Thank you for the compliments!

They do stack at longer draw weights. Most of the bows were made for arrows that were only 25-27" long.

It would have been nice to meet Steve in Utah last september. But i guess he is less active nowadays with flight and bow bulding, i get it.

There is quite a lot of things to play around with only wood bows, some of us are a bit more drawn to more and more problems!! Then you need sinew and horn hah.

300g weighing hornbow is a sight in those modern target shoots. Especially when you have the same cast as guys shooting skinny carbons with barebow!

This 50# bow shooting only 24" was flight only bow. Short draw, short arrow. Lots of speed and lots of cast.

I similarly got interested with hornbows because they last so much longer and can maintain same cast year after year. When you get the hang of it, they will last a lifetime. Some people are lucky though and learning can take years. ![]() Especially if you get bad luck with material and/or are stuck with wrong building techniques…

Especially if you get bad luck with material and/or are stuck with wrong building techniques…

Yes I’ve got to admit I have my internal hurdles I need to get over that’s for sure to really enjoy this hobby.You are one that is a breath of fresh air to me.I see many start out as hunters migrating to the flight shoot hobby too.

An example I’ll show if it’s proper of the area I live in and my quarry.It’s closed season now so the deer have relaxed somewhat.

I’ve found though that if self bows are made properly they can last decades also while maintaining performance.

Some people are just quick studies with this hobby or they have the desire to challenge themselves a bit more not afraid of failure.

I agree with your analysis of the other reasons why too.

Most of the fun I get from archery is hitting what I shoot at.I have not gotten enough confidence to shoot deer at 40 yards yet though.Although target shooting those distances is getting better somewhat…ha ha.

I’ve cut out a shorter length bow now.52" TTT.

I’m still going to want to get the 28" draw with the design yet though.This time I’ll get the deflex in there with the recurves of course.Bending the recurves before V splicing.

I was wondering how thick were those maple pieces you bent for those 10 examples of bows?I realize too they were green somewhat to help the process.

In using hickory here I soak the the dry wood for a day or so before boiling.Usually thickness is’nt much more than 9/16" for satisfactory results without too much splintering around 3/4" wide.Establishing center line prior to bending and usually tweaking them still yet after glueing the V splice.

I’ll see to try the laying it on it’s side tracing with a pencil the table top method with wide enough limbs to get a straight line.

With self bow staves I always jumped at the opportunity of making a bow from a stave that had a natural hump or knot in the handle area to give it a deflex coming out of the handle.It does’nt take much either.A lot of yew has that natural deflex also.

Same with a wiggle or knot removed in the arrow pass area to make it more center shot.

With this induced process with 3 parts the female V part of the limb and V male splice area of the handle will leave a gap at the point of the male part splice.This is what I’m figuring to do I guess.I’ll glue it then remove material from the belly of the limb in that area to make it flush to accept the horn that’ll go over top of it.

Is there an easier solution?

I’ve selected two slats of as perfect of hickory as I got for limbs and a scrap piece of osage for the handle.The slats and handle are as perfectly planed flat as possible of course to get as perfect a perpendicular joint as I can get on the handle splice.

I know osage can be oily but I’ve had good luck using it preparing the surface properly before glueing.

With all of the splices I’ve seen Jere do on here I’m positive he’s an expert at this…ha ha.

I get it, hunting you want to be certain of hitting. In those sporting ranges, 3D or field target, we shoot up to 80 yards for points. Sometimes hit good, but not with full confidence.

2023 i got 2nd place in IFAA field archery world championships at Pärnu, Estonia. I will say… i managed to do that because there wasn’t enough good archers!! ![]() Maybe 20 participants in the historical category (wood/horn bow + wood arrow).

Maybe 20 participants in the historical category (wood/horn bow + wood arrow).

My maple that i use for hornbows is kiln dried imported sugar maple. I don’t soak it, i just steam for 1 hour and then use veritas strap to bend it. Same strap as furniture makers use. It makes it so much easier… I think originally for core pieces, turks used somewhat fresh wood. Fresh wood when boiled can do wonders too.

I don’t have a good source for fresh maple here in Finland so i need to work around it. Local wood isn’t up to par with sugar maple. I did some bend tests and our local maple (norwegian maple - acer platanoides) was some 30% weaker than sugar maple, while having same mass. ![]()

Kiln dried maple works really nicely despite the myths of being somehow weaker or brittle.

This gap is not something you need to worry about. Just try to make it as small as you can. Sinew layer will take the stress and not break the joint. If you would want to make it perfect, you need to work the grip piece a little different to accomodate the deflex angle. You will see this if you look closely at the two pieces now with “regular” joint angle.

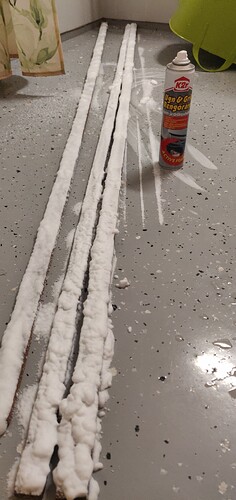

Best trick for getting rid of oil is oven cleaner foam spray. I got it from this one guy from PA, i was really impressed with his short sinew bows. Sometimes packing 70-100#! I think he is german.

But anyway, many people recommend the oven cleaner. With some osage its necessary, but it might be only with those really dark osage pieces.

Here is before and after oven cleaner when i was making laminated bows with IPE:

Yes his name is Simon and he’s from Germany.“Stonehill Bows”.I’ve heard of that also.

Talked with him a few times.Heck of a bow maker.Voted many a time for his bows to be “bow of the month”.Not sure if he puts his bows through the endurance test though.