Start sizing today. Is this the greyish color that Adam writes about ? I’m sure there are no air bubbles, but some parts of the horn turned grey after 10 layer of fish glue.

No that is not. At least by what i can see from here.

These grey bubbles would appear only in the bottom of the grooves. Grey color comes from the bubbles. Basically glue is losing contact/power there and this will only spread when glue is aging. So in such case sizing should always be started over.

It disappeared overnight ! I couldn’t even sleep properly I was rethinking sizing process over and over trying to figured out what I did wrong. It’s all black now ![]()

Ok now I have these bubbles. They formed on the fourth day of sizing and when I wash them away, they where on the bottom. So I guess the hide glue on the top contracted and pulled first layers fish glue from the horn. The temperature of horn is only 14-16 C. I think that is the issue, fish glue does not penetrate cold horn properly.

Maybe yes, but your glue is hot right?

Humidity has always been my only issue, if its under 50%, the glue fails.

The temperature of fish glue was maybe 50C because I realized later that the glue is 10 degrees cooler then water where my thermostat is. Humidity is 35-45%. Now I’m starting with 2% hide glue and horn would be in hot box for 10 minutes before first few layers.

Humidity is 100% your problem. Wait for 50-70% humidity and the effort is not wasted.

I had a period (in 2020) when i couldnt get the glur to work at all. I tried different solutions up to 1%, fish glue, hide glue. Different temperatures, heated surface, different brush, laying horns flat or on the side. Only issue i couldnt change was the humidity even when i had a vaporizer machine that added 5-10%. My humidity was still 30-45%.

I even tried a box that i kept the horns in after sizing. I had a water plate that kept humidity in 70%, but it didnt work. It smelled a lot and the horn didnt dry.

In the end i spend experimenting about 3 months, daily. Washed off 20 times the glue (from some 15 horns and hundreds of layers) and didnt get it to work. When summer came and it was 55% humid in the apartment, i made the glue up first try. ![]() Hope this helps.

Hope this helps.

And the result was always bubbles in low humidity ? Ok thanks, I will try it just one more time with hide glue only. And then I will wait for the summer. Just one more time ![]()

Yeah, that is exactly what I’ve got. I’m glad that you can see poor adhesion before gluing it to the core.

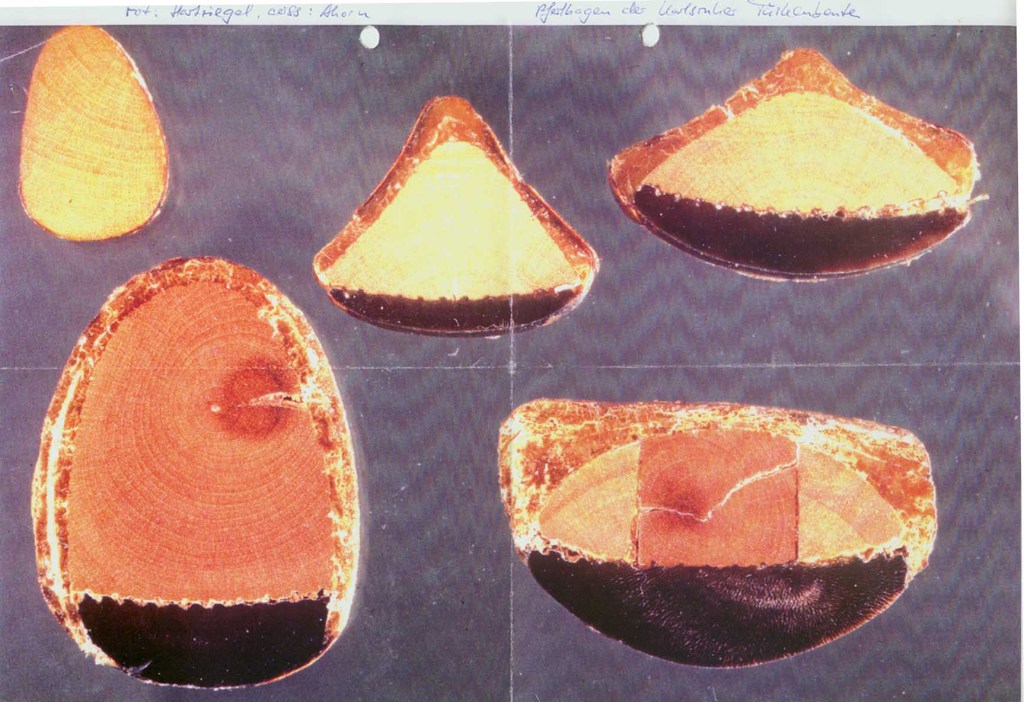

I’m on 12 layer and bubbles starting to show up again. But it is better then first time. Humidity raised to 45-55%. Maybe my grooves are too pointy and deep compared to grooves that I’ve seen on old bows.

Nice pictures. Its true the bows were made like that, cross sections don’t lie. It can be copied if you so want.

On the other hand, as Ivar has said, why not make it better? Its still a matter of craftmanship, we are not cnc tooling or automating it to laser precise dimensions. The sharp and deep grooves add more adhesion area and do make a difference. Meaning if your glue isn’t the strongest, or you make a small mistake on the way, your glueline should be still strong. This goes to also your bow form, bad tiller, too much reflex or dimensions. Gives you a buffer of protection, if some other issue comes up.

Where as if you keep the glue area to the minimum, you need to always have it perfect, otherwise a risk of breakage is there.

If you have even small amount of bubbles, you run the risk of developing more on the way you move to thicker glue layers.

Ok, after 5th washing, I’m going to glue horn flat. It’s not a flightbow so … I just can’t wait for summer ![]()

Oh damn, not sure what you mean. Hopefully it goes well. I have always had grooves in my horns.

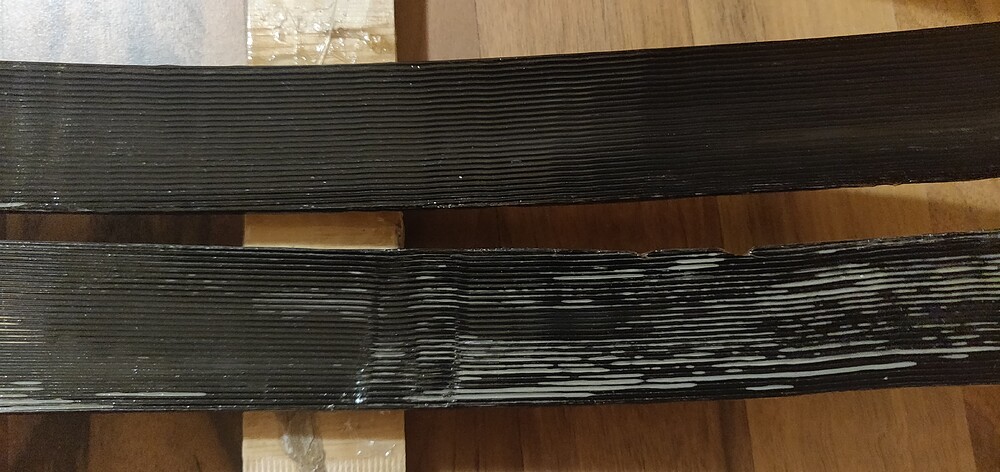

Finally, grooves are full !

I made smaller grooves maybe 0.5mm and I use my finger instead of brush because of bubbles.

But what I think helped most was that I switch to stronger glue. From 200 to 250.

200 glue doesn’t gel even in refrigerator under 4 hours at low concentration. 250 gels in one hour.

And during sizing only 250 glue gels before it dries in my workshop.

My method was

3% glue 30 layers

20% 3 layers

No heating

Workshop was 16C and 40-50% humidity.

Sounds weird, but if it works… Maybe your glue was spoiled?

Basically the root problem with these voids is too strong shrinking. So one would think adding more glue strength creates the situation even worse? I don’t know what bloom strength my hide glue is, but it gels just fine even in 25 degrees celsius.