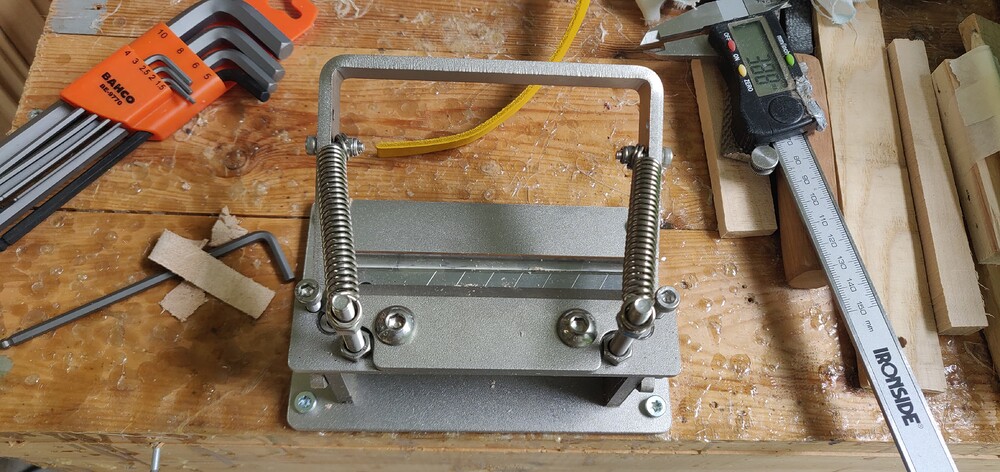

I recently bought this cheap leather thinning device through aliexpress. Cost was only 70 euros, since its so simplistic. Professional machines go far past 1000e.

Build quality is good, machine is full metal and it can actually give good cuts, if the blade is sharp and you use good technique. For 5cm wide strips the lowest i could go was 0,3mm. But maybe more even cut and still thin was 0,35mm.

I highly recommend, if 0,35mm is sufficient for backing a bow.

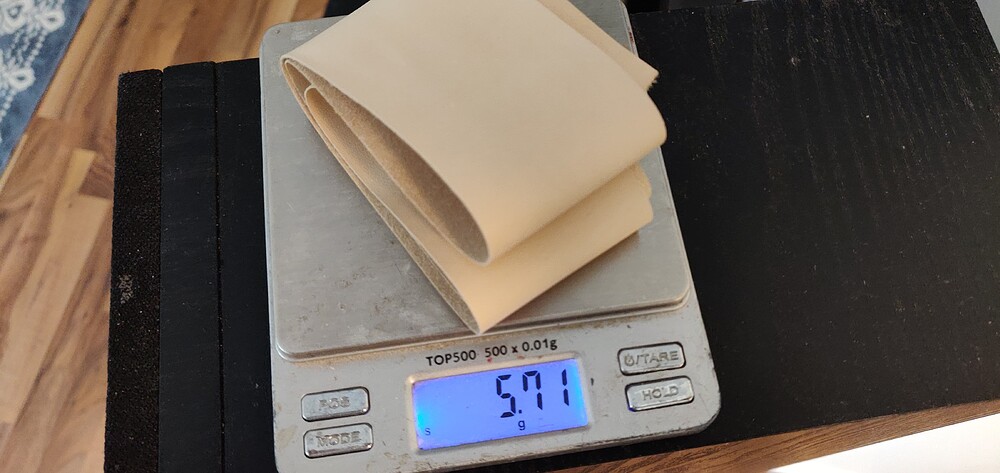

The leather that i split here was 1mm calf leather. I’m planning to cover some turkish bows with the leather.

Thanks for the tip, I was planning to use a drum sander. Probably stupid Idea.

I have used a normal table top sander for the sidestrips. Works fine, you dont need such consistency for thickness. But wider pieces must become hard to manage…

Great jig. I’ve tried thin side strip from cow leather and get 0.15 mm without problem.

Nice! Is it vegetable tan? I don’t know that much about leather but the surface somehow reminds me of chrome tanned??

Yes, it is vegetable tanned. 4.5cm cow leather was difficult to get under 0.6mm safely, I hope calf will be easier.

Hi Marek I would love to see the way you glued this leather to the bow.

I have baby goat leather but is like paper, it wrinkles because the difference of shape in the handle and kasan

I will experiment by soaking the leather in water. To check if it becames softer and adapts better.

I bet the soaking in water will solve your problem.

Cool tool Jere.Plenty wide enough for bows.All vegtable tanned leather I presume also.That’s just a shade over heavy duty typing paper thickness and about as thick as I get my birch bark,but birch bark always seems to dent and damage too easily.

It beats the old eye ball sanding technique by a bunch.

Yep, i would moisten that goat leather too. There is a little bit of shaping to do anyways around the grip. No dry leather would seem possible to apply there.

Ed: Funnily there were some guys critiqueing this thinning machine, calling the outcome too thick still?? Leather was anyway applied to target and warbows, not flight bows. So yeah, its good, i can recommend the machine.

Once one applys an oil varnish type finish the bow is for all practical purposes water proofed.

Surprising though how much extra weight that will involve yet,but probably of no consequences to performance though.