is this an authentic manufacturing method?

Which one do you mean? As far as i know all of these are. Turkish/ct used to be 3-piece construction and manchu 5 or 7 piece.

Scythian is a bit more complicated, but generally yes this is also accurate. They had some added sidestrips that created width, but maybe not all? But in total, very small pieces of wood were used.

And horn strips sandwiched in the middle. The bow will have belly horn strips, you just need to wait until i get there.

я про скифский лук, значит способ которым сделал стилиян стефанов не верный?

Edit by Admin:

Google Translator: “I’m talking about a Scythian bow, so the way that Stefanov’s stylian did is wrong?”

@castorbowhunter Please use English.

sorry

please excuse me

the question is still the same! I am interested in the historical reliability of this particular method of making Scythian onions, even if they did not have suitable wood, although this is doubtful and there were no horns either? why cut a good horn into pieces? I remember seeing a photo there just a strip is cut out of the side of the horn

Well as far i understood, handle should have horn in the middle also. And the core is built from 5 pieces. Stiliyan has 3. Its ok, i don’t know what is right or wrong. Many ways to do.

The thin horn strips in the middle are side walls, so its pretty much waste material.

But i find problematic to make the bow so it has a ton of reflex, as Stiliyan has. It might make the bow really unstable. At least i can’t brace and balance such bow really easily.

Some Scythian bows were made this way, with horizontal laminations of small pieces. Others were made from vertical laminations of small pieces – wood on the left and right, horn in the center, and the whole spiral wrapped in sinew.

Why small pieces? They were probably trying to avoid the hassles (in 300 BC) of steam bending longer pieces into the appropriate shapes. They used smaller, naturally shaped pieces of wood and then matched those shapes with smaller pieces of horn.

Do you have a source for horizontal laminations?

What i have seen the bows were built with vertical strips (horn in the middle), but also with horn strip on the belly as usual for other bows.

Just things I remember from years ago on the old ATARN, written by Jack Ferrell when he made his Scythian. What you are setting up is what I call horizontal laminations running from side to side, like a modern laminated bow. Vertical laminations run from back to belly, at right angles to modern bow building technique.

No, what i have here is very much vertical strips of wood and horn. Those pieces are 15mm thick.

Scythian is progressing. Only need to splice them now. Hopefully i have enough core thickness. I’m chasing something shootable, maybe 55-90 pounds. I try to have the length and overall shape as close to original. Maybe a tiny bit narrower if i have less poundage?

Another interesting bow  Will be great to see how it turns out.

Will be great to see how it turns out.

Interesting for sure… I hope i have enough length for proper v-joints. Something like 8cm long joints. 10cm would be better but i don’t have the luxury.

Couple of joints… Really hard to get it align perfectly, so i think this will do. When i glue it i’ll clamp it straight with boards and a bench.

Looking really good so far. Good luck on the rest of the build. I think you’ll have plenty of draw weight there…

That’s come along VERY nicely! When do you plan to open it out and string it up?

Thank you! I have tiny concerns i made the handle too thin, but i will give it extra thick sinew coat and i suppose its fine.

Now it has 2 layers of sinew, i want to give one last one, then few weeks of seasoning. Maybe opening by end of january? Its very dry in Finland during winter, so there is zero doubt sinew layers can dry even in matter of 1-2 weeks.

We’ll see!

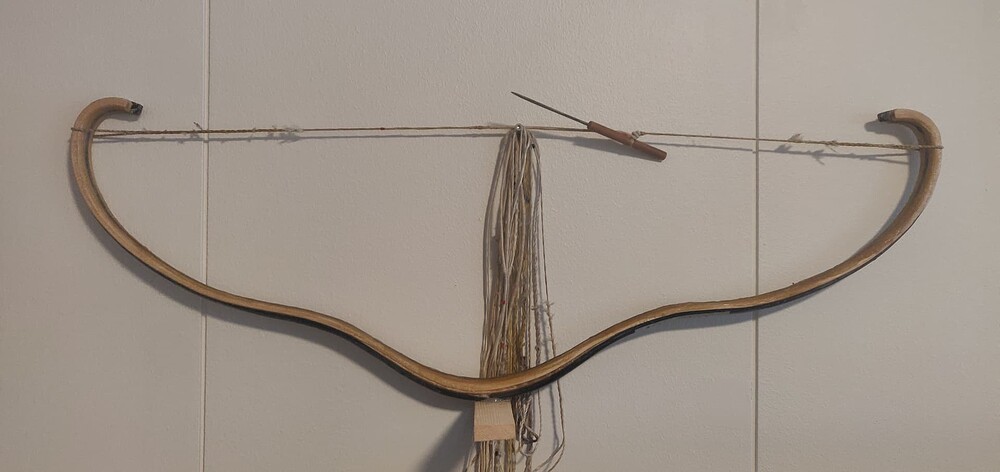

Yesss… its alive. And its very eager to bend, even though feels super heavy. I tried to get a 130cm bow, but somehow i ended up with 115cm?? This has been happening lately!  Its just a matter of more stacking and less draw length.

Its just a matter of more stacking and less draw length.

I will definitely try to work this to some poundage that i can actually use it for shooting.

Now it weighs about 450-500g. It got about 4mm thick sinew backing. So thickness at the bending parts is 17mm.